ISO 9001 work instructions provide a structured format for documenting processes, ensuring clarity and compliance with quality standards. They outline steps, responsibilities, and required outcomes, fostering consistency and efficiency in operations. By following this format, organizations can align their procedures with international quality management system requirements, enhancing overall performance and customer satisfaction.

1.1 Importance of Work Instructions in ISO 9001

Work instructions are essential for ISO 9001 compliance, as they provide clear, detailed steps for tasks, ensuring consistency and reducing errors. They standardize processes, making it easier to train employees and maintain quality standards. By documenting procedures, organizations can ensure compliance with ISO requirements, improve efficiency, and enhance customer satisfaction; These instructions also serve as a reference for audits, demonstrating adherence to quality management principles and fostering a culture of continuous improvement.

1.2 Brief Overview of ISO 9001 Standards

ISO 9001 is a globally recognized standard for quality management systems (QMS), providing a framework for organizations to ensure customer satisfaction and continuous improvement. It focuses on key principles like customer focus, leadership, and process approach. Published by the International Organization for Standardization (ISO), it emphasizes documentation, accountability, and consistency in processes. Companies adopting ISO 9001 demonstrate their commitment to delivering high-quality products/services, meeting regulatory requirements, and achieving operational efficiency. The standard is applicable across industries, offering a flexible and scalable framework for quality management.

1.3 Purpose of Work Instructions

Work instructions serve as detailed, step-by-step guides that outline specific tasks and processes to ensure consistency, compliance, and quality. They provide clear direction to employees, reducing errors and variability in operations. By standardizing methods, work instructions align activities with organizational goals and ISO 9001 requirements. They also act as a reference for training, audits, and continuous improvement initiatives. Their purpose is to ensure that tasks are performed efficiently, safely, and in accordance with established quality standards, fostering accountability and transparency across the organization.

Key Components of Work Instruction Format ISO 9001

Key components include document identification, scope, responsibilities, detailed procedures, quality compliance, and revision control, ensuring clarity and alignment with ISO 9001 standards.

2.1 Document Identification and Control

Document identification ensures each work instruction has a unique identifier, version number, and date. Control mechanisms include approval processes, access restrictions, and traceability. This guarantees that only authorized, up-to-date documents are used, preventing errors. Proper identification and control align with ISO 9001 requirements, ensuring compliance and consistency. It also includes a clear document title, reference numbers, and revision history. These elements help maintain integrity and facilitate audits, making it easier to track changes and ensure adherence to quality standards across the organization.

2.2 Scope and Applicability

The scope section defines the specific processes, activities, or departments to which the work instruction applies. It clarifies the relevance and application of the document, ensuring it is used appropriately. This section outlines the intended audience, roles, and responsibilities, preventing misapplication; By clearly stating the operational boundaries, the work instruction aligns with ISO 9001 requirements, ensuring consistency and compliance. It also specifies the conditions under which the instructions are mandatory, avoiding ambiguity and promoting effective implementation across the organization.

2.3 Responsibility and Accountability

The responsibility section clearly defines the roles and accountability of individuals or departments involved in executing the work instruction. It specifies who is responsible for task completion, oversight, and compliance with ISO 9001 standards. Accountability ensures that individuals understand their duties and the consequences of non-compliance. This section promotes a culture of ownership and transparency, aligning actions with organizational goals. By assigning clear responsibilities, the work instruction enhances operational consistency and compliance, ensuring that quality standards are maintained throughout the process.

2.4 Detailed Step-by-Step Procedures

Detailed step-by-step procedures are the core of ISO 9001 work instructions, outlining the exact actions to be taken in a sequential manner. These procedures must be clear, concise, and actionable, ensuring tasks are performed consistently and correctly. They should include specific instructions, tools required, and expected outcomes at each stage. The use of visual aids or examples can enhance clarity. By breaking down complex processes into manageable steps, employees can follow the instructions without ambiguity, ensuring compliance with quality standards and reducing the likelihood of errors.

2.5 Compliance with Quality Standards

Compliance with quality standards is a critical aspect of ISO 9001 work instructions. These documents must align with the organization’s quality objectives and policies, ensuring adherence to established processes and procedures. Work instructions should reference relevant ISO 9001 clauses and provide clear guidance on meeting quality requirements. Regular audits and reviews help verify compliance, ensuring consistency and alignment with the standard. This fosters a culture of quality, minimizing deviations and enhancing overall organizational performance.

2.6 Revision and Update Process

The revision and update process ensures work instructions remain current and effective. Changes are initiated when processes, standards, or regulations evolve. A formal approval process is required before updates are implemented. Revised documents are marked with version control, and employees are notified. Training is provided to ensure understanding of updates. This process maintains compliance with ISO 9001 and supports continuous improvement. Regular reviews help identify outdated content, ensuring instructions align with organizational goals and quality standards.

Best Practices for Creating Effective Work Instructions

Use clear, concise language and a structured format. Include visuals for complex steps and ensure accessibility. Regularly review and update instructions to maintain relevance and compliance with ISO 9001 standards.

3.1 Clarity and Precision in Language

Clear and precise language is essential for effective work instructions. Avoid ambiguity by using simple, direct terms. Ensure each step is unambiguous and free from jargon. Use active voice and present tense for consistency. Define technical terms if necessary. Highlight critical steps or safety precautions to prevent errors. Use bullet points or numbered lists for readability. Review instructions to eliminate redundant information. Ensure terminology aligns with ISO 9001 standards. Test instructions with employees to confirm understanding. This approach ensures tasks are performed correctly and consistently, reducing errors and improving compliance.

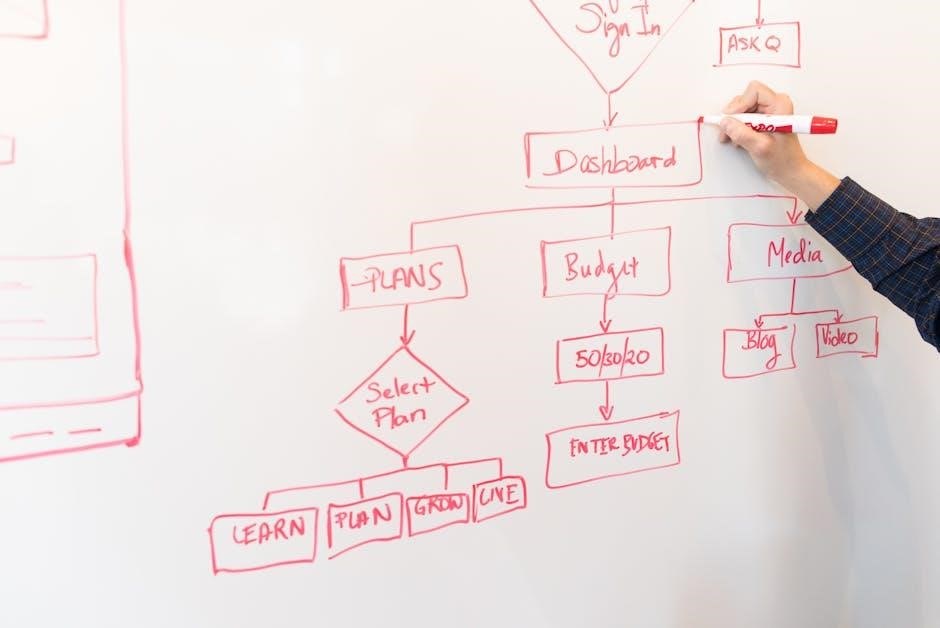

3.2 Use of Visual Aids and Diagrams

Visual aids and diagrams enhance clarity in work instructions, making complex processes easier to understand. Use flowcharts, diagrams, or images to illustrate key steps or equipment. Screenshots or videos can demonstrate tasks visually. Ensure visuals are clear, high-quality, and directly relevant to the text; Place diagrams near corresponding instructions to avoid confusion. Use color-coding or symbols to highlight critical steps. Visuals should comply with ISO 9001 standards and be updated when procedures change. This approach reduces ambiguity and improves compliance, ensuring tasks are performed accurately and efficiently.

3.3 Accessibility and Distribution

Ensuring accessibility and proper distribution of work instructions is critical for ISO 9001 compliance. Make instructions available in easily accessible formats, such as digital documents or printed copies, depending on employee needs. Use a centralized repository or document control system to store and share files. Ensure all relevant staff receive updates and revisions promptly. Train employees on how to access and interpret the instructions. Regularly review distribution lists to confirm the right personnel have the latest versions. Accessibility and clear distribution ensure everyone follows consistent procedures, maintaining quality and compliance.

3.4 Training and Competency Assessment

Training and competency assessment are essential for ensuring employees understand and follow work instructions effectively. Provide regular training sessions to cover new or updated procedures. Assess employees’ knowledge through quizzes, practical demonstrations, or observations. Maintain records of training and assessment outcomes for compliance. Ensure only competent individuals perform tasks outlined in the work instructions. Continuous improvement can be achieved by incorporating feedback and updating training materials accordingly.

3.5 Regular Review and Feedback Mechanism

Implementing a regular review and feedback mechanism ensures work instructions remain relevant and effective. Schedule periodic reviews, such as quarterly or annually, to assess their accuracy and relevance. Encourage employees to provide feedback on clarity, usability, and any gaps. Use this feedback to identify areas for improvement and update the instructions accordingly. Document the review process and maintain records for compliance. This mechanism fosters a culture of continuous improvement and aligns with ISO 9001’s emphasis on ongoing enhancement of processes.

Implementation of Work Instructions in ISO 9001

Effective implementation involves developing templates, securing approvals, training staff, and monitoring adherence. Regular audits ensure compliance, while documentation of deviations supports corrective actions and continuous improvement.

4.1 Developing a Work Instruction Template

Creating a work instruction template involves outlining the purpose, scope, and structure. It should include document identification, revision history, approvals, and detailed procedures. The template must ensure clarity, accessibility, and compliance with ISO 9001 standards. It should be user-friendly, with clear sections for step-by-step instructions, responsibilities, and quality checks. Collaboration with stakeholders is essential to tailor the template to organizational needs, ensuring consistency and effectiveness across all departments. Regular reviews and updates maintain its relevance and alignment with changing requirements.

4.2 Approving and Publishing the Document

Approval and publishing are critical steps to ensure the work instruction is officially recognized and implemented. The document must be reviewed and approved by authorized personnel to confirm compliance with ISO 9001 standards. Once approved, it is published and distributed to relevant departments. The final version should include approval dates and signatures. Electronic or hard copies are disseminated, with access controlled to prevent unauthorized modifications. Version control ensures only the latest approved document is in use, maintaining consistency and compliance across the organization.

4.3 Training Employees on New Procedures

Training employees on new procedures is essential for effective implementation of work instructions. It ensures understanding and consistency in following the documented processes. Training sessions should be interactive, such as workshops or hands-on simulations, to engage employees; The training should also include review of the work instruction document, highlighting key steps and responsibilities. Assessments or feedback mechanisms can verify employee comprehension. Regular refresher training is recommended to maintain proficiency and adapt to updates. This step ensures the workforce is competent and aligned with ISO 9001 requirements.

4.4 Monitoring Compliance and Effectiveness

Monitoring compliance and effectiveness ensures that work instructions are followed correctly and achieve their intended outcomes. Regular audits and checks should be conducted to verify adherence to procedures. Performance metrics, such as defect rates or cycle times, can measure effectiveness. Feedback from employees and supervisors should be collected to identify gaps or inefficiencies. Corrective actions must be implemented promptly to address deviations. Continuous improvement initiatives should be integrated to refine processes and ensure alignment with ISO 9001 standards. This ongoing oversight maintains quality and operational consistency.

4.5 Documenting Deviations and Corrections

Documenting deviations and corrections is crucial for maintaining transparency and accountability. Any departure from the work instructions must be recorded, including the nature of the deviation, its cause, and the corrective actions taken. Supervisors should approve these records, ensuring they are accurate and complete. This documentation serves as a reference for future audits and continuous improvement initiatives. It also helps identify systemic issues and prevents recurring errors. Proper storage of these records ensures traceability and compliance with ISO 9001 requirements, fostering a culture of accountability and quality.

Tools and Resources for Work Instruction Development

Essential tools include document control software, flowchart creators, QMS platforms, and checklists, ensuring efficient, standardized, and compliant work instruction development aligned with ISO 9001 standards.

5.1 Word Processing and Document Control Software

Word processing tools like Microsoft Word or Google Docs enable clear, structured drafting of work instructions. Document control software ensures proper version management, approval workflows, and secure storage. Features like templates, track changes, and collaboration enhance consistency and accuracy. Integration with QMS platforms streamlines compliance with ISO 9001 standards. These tools prevent unauthorized edits, maintain document integrity, and facilitate easy retrieval. Regular updates and access controls ensure employees use only current versions, promoting operational efficiency and adherence to quality standards across the organization.

5.2 Flowchart and Mind Mapping Tools

Flowchart and mind mapping tools visually organize processes, enhancing clarity for work instructions. Software like Lucidchart or MindMeister helps create step-by-step diagrams, reducing ambiguity. These tools ensure procedures align with ISO 9001 by breaking down complex tasks into manageable steps. Visual representations improve understanding and compliance, allowing employees to follow instructions more effectively. Collaboration features enable teams to review and refine workflows, ensuring accuracy and consistency. These tools are essential for developing clear, structured work instructions that meet quality standards and promote operational efficiency.

5.3 Quality Management System (QMS) Platforms

Quality Management System (QMS) platforms are essential tools for developing and managing work instructions under ISO 9001. These platforms streamline document control, versioning, and access, ensuring that employees follow the latest approved procedures. QMS platforms also enable integration with ISO standards, tracking compliance, and generating audit trails. Features like automated workflows, role-based access, and real-time updates enhance efficiency and reduce errors. By leveraging QMS platforms, organizations can maintain consistent quality processes and easily demonstrate compliance during audits and certifications, aligning with ISO 9001 requirements.

5.4 Checklists and Verification Templates

Checklists and verification templates are essential tools in creating effective work instructions under ISO 9001. They ensure tasks are completed accurately and consistently by breaking down complex processes into manageable, actionable items. These tools help reduce errors, enhance compliance, and simplify auditing by providing clear evidence of completed tasks. Checklists are particularly useful for repetitive processes, while verification templates ensure adherence to quality standards. Both tools can be customized to specific workflows and integrated with the Quality Management System (QMS) for seamless verification and documentation.

- Enhance task accuracy and compliance.

- Provide clear audit trails for verification.

- Support continuous improvement initiatives.

Common Mistakes to Avoid in Work Instruction Creation

Common mistakes include overly complex language, omitting critical steps, and failing to update documents. Additionally, using unapproved templates and neglecting employee training are frequent errors.

- Using ambiguous terminology without clear definitions.

- Not including revision dates or approval statuses.

- Overloading instructions with unnecessary information.

- Not aligning procedures with actual workplace practices.

- Ignoring the need for visual aids or diagrams.

6.1 Lack of Specificity and Detail

One common mistake in creating work instructions is the lack of specificity and detail. Vague or ambiguous steps can lead to confusion among employees, resulting in inconsistent processes and potential non-compliance with ISO 9001 standards. Clear and detailed instructions are essential to ensure tasks are performed correctly and consistently. Without specific guidance, employees may interpret steps differently, leading to errors and inefficiencies. It is crucial to define each action precisely, avoiding general statements that leave room for misinterpretation.

Additionally, including visual aids like diagrams or flowcharts can enhance clarity. Employees should understand exactly what is expected at each stage of the process. Regular reviews and updates can help maintain the relevance and effectiveness of the work instructions, ensuring they remain aligned with organizational goals and quality standards. Proper training on these documents is also vital to prevent misunderstandings and ensure compliance.

6.2 Outdated or Unapproved Documents

Outdated or unapproved documents are a common issue that can lead to non-compliance with ISO 9001 standards. Work instructions must be regularly reviewed and updated to reflect current processes and standards. Using obsolete documents can result in incorrect procedures, quality issues, and audit failures. Organizations should implement robust document control processes to ensure only approved versions are in use. Automated systems or version control tools can help track updates and prevent unauthorized access to outdated materials. Regular audits should verify the currency and approval status of all work instructions to maintain compliance and effectiveness.

6.3 Poor Formatting and Readability

Poor formatting and readability are common pitfalls in work instructions, leading to confusion and errors. Inconsistent fonts, lack of headings, and dense text can make documents hard to follow. This issue often arises from inadequate formatting guidelines or insufficient training. To address this, use clear headings, bullet points, and visuals like diagrams or flowcharts. Regularly review documents to ensure they are visually appealing and easy to understand. Proper formatting is essential for maintaining clarity and ensuring compliance with ISO 9001 standards, which emphasize clear communication and effective documentation.

6.4 Insufficient Training and Awareness

Insufficient training and awareness are common pitfalls in work instruction implementation. Employees may not fully understand the procedures, leading to non-compliance and errors. Without proper training, staff may misinterpret steps or fail to recognize the importance of adherence. This can result in inconsistent outcomes and quality issues. Organizations must ensure that all personnel receive comprehensive training and regular updates on work instructions. Refresher sessions and visual aids can enhance understanding and ensure everyone is aligned with ISO 9001 standards.

- Conduct regular training sessions;

- Provide easy-to-understand materials.

- Ensure accessibility for all employees.

6.5 Non-Compliance with ISO Standards

Non-compliance with ISO 9001 standards in work instructions can lead to audit failures, legal penalties, and loss of certification. Key issues include incorrect documentation, incomplete procedures, and deviation from standard requirements. Employees may unknowingly follow outdated practices, causing systemic errors. Regular audits and training are essential to ensure alignment with ISO standards. Organizations must integrate compliance checks during the drafting and approval phases of work instructions to mitigate risks. Ignoring compliance can undermine the entire quality management system, affecting customer satisfaction and business credibility.

Continuous Improvement of Work Instructions

Continuous improvement ensures work instructions remain effective and aligned with ISO 9001 standards through regular audits, feedback, updates, and refresher training, fostering a culture of ongoing enhancement.

7.1 Conducting Regular Audits

Regular audits are essential for ensuring work instructions align with ISO 9001 standards. These audits evaluate compliance, accuracy, and effectiveness of procedures. They identify gaps, non-compliance, or outdated practices. Audits involve reviewing documentation, observing processes, and interviewing employees. Findings are documented, and corrective actions are implemented. Audits promote continuous improvement by highlighting areas for refinement. They also ensure that work instructions remain relevant and effective over time. Regular audits foster a culture of accountability and quality, which are vital for ISO 9001 certification.

7.2 Gathering Feedback from Employees

Gathering feedback from employees is crucial for refining work instructions under ISO 9001. Regular surveys, suggestion boxes, or one-on-one meetings allow staff to share insights on procedure clarity and effectiveness. Anonymous submissions can encourage honest input, helping identify pain points or inefficiencies. Feedback should be reviewed and acted upon, with updates communicated to ensure continuous improvement. This inclusive approach fosters a culture of ownership and ensures work instructions remain relevant and practical. Recognizing contributors further boosts engagement and collaboration in the improvement process.

7.3 Updating Procedures Based on New Standards

Updating work instructions based on new ISO 9001 standards ensures compliance and alignment with evolving quality management requirements. Organizations must periodically review and revise their procedures to reflect changes in regulations, industry practices, or technological advancements. This process involves identifying obsolete steps, incorporating new methodologies, and ensuring all updates are approved and documented. Employees should be trained on revised procedures to maintain consistency and effectiveness; Regular updates also help in addressing gaps and improving overall process efficiency, ensuring the organization remains certified and competitive.

7.4 Refresher Training and Awareness Programs

Refresher training and awareness programs are essential for maintaining employee proficiency in following work instructions. These programs ensure that staff remain updated on the latest procedures, standards, and changes in ISO 9001 requirements. Regular sessions reinforce learning, prevent knowledge gaps, and promote a culture of continuous improvement. Hands-on activities, real-world examples, and updated materials help employees apply their knowledge effectively. Such initiatives also foster accountability and alignment with the organization’s quality objectives, ensuring sustained compliance and operational excellence.

Effective work instructions are essential for maintaining compliance with ISO 9001 standards, ensuring operational consistency, and driving quality outcomes. By adhering to the outlined format and best practices, organizations can create clear, actionable documents that enhance productivity and reduce errors. Continuous improvement through regular audits, feedback, and updates ensures work instructions remain relevant and aligned with evolving standards. Investing time in developing robust work instructions pays off in terms of efficiency, compliance, and employee confidence, ultimately supporting the organization’s commitment to quality management.